BoreSite® Services

A rugged, on-premises computing system that safeguards and processes field data right at the source, ensuring continuous uptime and real-time insight.

BoreSite® Inject – A fully automated chemical injection system that delivers precise dosing, reduces waste, and optimizes field performance.

BoreSite® Data Vault – A secure, cloud-based portal with infinite retention, giving you full control and instant access to historical well data anytime, anywhere.

Unlock the Full Value of Your

Operational Data

From intelligent chemical injection and on-site edge computing to secure, long-term data storage, BoreSite equips operators with field-proven solutions that reduce costs, optimize performance, and empower smarter, data-driven decision-making.

BORESITE® EDGE

Unlock the Full Value of Your

Operational Data

Key Features:

- Modular hardware for rapid deployment and vendor integration

- Secure, low-latency data streaming to BoreSite® Cloud or local dashboards

- 3rd party data integration, IoT connectivity, and wireless communication

BORESITE® INJECT

Smarter Automation for Smarter Jobs

Key Features:

- Real-time adjustment based on live flow rates (0.01–6.0 gallons)

- High-flow 4″ flow meter with intuitive touchscreen HMI

- Remote login and monitoring from any device

- Seamless integration with BoreSite® Edge for optimized drill-out operations

- Five serviceable chemical pumps and compact durability for quick rig-up/rig-down

- 24/7 DWS support and proven chemical savings compared to conventional systems

- Modeled Torque & Drag Simulations for optimizing chemical and fluid efficiency

BORESITE® DATAVAULT

Secure, Cloud-Based Data Retention

Key Features:

- Row-level security (only you access your data)

- Infinite, secure storage with Microsoft authentication

- Instant downloads in raw CSV formats for internal analysis

Real-Time Visibility – Anywhere in the World

Customizable Alarms and Dashboards

From remote monitoring of pit levels to setting drill out operational parameters & notifications, our fully customizable dashboard & user reports allow you to view the data that matters most – delivered the way you want it.

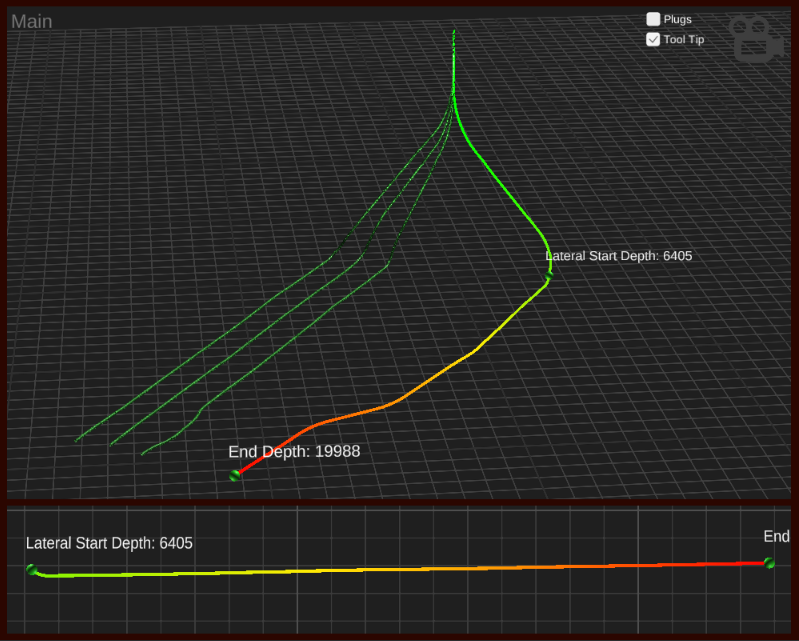

Real-Time Automated Plug Tracker

Our real-time automated plug tracker improves data accuracy, provides plug by plug KPIs, and eliminates pen to paper data collection during the frac plug drill-out operation.

Built-In Data Analytics and User Reports

Built-in data analytics providing access to current & historical well KPIs, After-Action Reviews, NPT reports, Rig comparisons, and other key data sets to drive continuous improvement.

Planned vs Actual (PVA)

Our BoreSite® Planned vs Actual (PvA) KPI feature allows your team to make immediate onsite improvements by comparing historical data vs your current operations in real time.

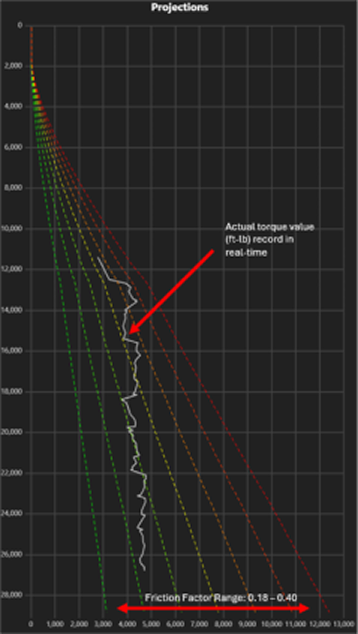

Model Torque & Drag Simulator

Use overlapping T&D modeled vs real-time drilling data provides full clarity on changing downhole conditions, and circulation programs to optimize downhole performance.

Use torque trends, friction factors, and load profiles to fine-tune chemical injection rates, mud properties, and drilling parameters. Teams can safely increase ROP, reduce waste, and maintain a stable, well-conditioned hole—without sacrificing performance or safety.

BoreSite® automatically pulls and synchronizes torque, drag, and drilling parameters from your rig systems and IoT devices, ensuring every model is continuously updated. The result is a unified, reliable dataset that supports accurate simulations and data-driven optimization across the entire well.

3D Modeling